What is butt welding?

Butt welding is used more and more in modern metal processing, through the butt welding technology, the same metal or dissimilar metal such as copper and aluminum can be firmly butt together. With the development of industry, butt welding technology is more applied to electronic and electrical, new energy vehicles and other industries. The following article will answer the knowledge of butt welding for you in detail.

Basic Concept of Butt Welding

The so-called butt welding is to place the two workpiece ends relative to each other, apply pressure at the same time, use welding current to heat, and then form a welding joint under the action of pressure, an efficient and easy to achieve automation welding process method.

The Types of Butt Welding

Butt welding is mainly divided into resistance butt welding and flash butt welding

Resistance butt welding

Resistance butt welding is a kind of solid phase welding in high temperature plastic state, and the joint connection can be recrystallization and mutual diffusion in essence, but all are solid phase connection.

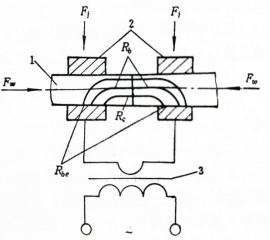

The principle of resistance butt welding and joint formation are shown in Figure 1.

Figure 1. Resistance butt welding schematic diagram

1- Weldment

2- Electrode

3- Solder resistance transformer

4-Ff- clamping force

Fw- forging force

Rb- weldment resistance

RC-Contact resistance

Rbe- Contact resistance between the weldment and the workpiece

Flash Butt Welding

The connection essence of the flash butt welding joint is the same as that of the resistance butt welding joint, which is also a solid phase connection, but the formation process has its own characteristics. At the end of the flash, a liquid metal layer has been formed on the end face. During the top forging, the end face metal is first integrated under the liquid phase. Then the liquid phase layer will be squeezed out of the joint end face under the action of the top forging pressure. After the flash butt welding machine welded parts, the joint is very strong, such as a metal tube through the flash welding, then through the tube bending machine bending at the joint, the joint will not break. There may be dust in the welding process, which can be absorbed by the side channel blower.

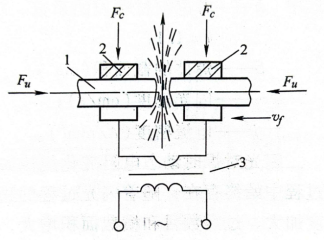

The principle of flash butt welding and joint formation are shown in Figure 2 :

Figure 2. Flash butt welding schematic diagram

1- Weldment

2- Electrode

3- Solder resistance transformer

4- Fc- clamping force Fu- forging force Vf flash speed

Advantages of Butt Welding

a) Resistance butt welding equipment is simple, fewer welding parameters, easy to master, easy to achieve automatic control;

b) Small reduction of resistance butt welding parts, saving materials, less burrs, which is conducive to simplifying the latter process;

c) flash butt welding has high thermal efficiency, can weld large-area parts, and has been used for welding gas pipelines with a cross-sectional area of 100000mm2;

d) flash butt welding because the lintel exists for a short time, only a few milliseconds, its position changes randomly, and the total time of heating throughout the end face of the weldment is more uniform, so continuous flash welding can not only weld a compact section, but also weld welds with expanded sections (such as thin sheets, etc.);

e) At the end of the flash, a thin layer of liquid metal will be formed on the surface of the weldment, so that the oxide impurities on the surface are easy to discharge with the liquid metal at the top section of the interface, so that the flash butt welding joint is of high quality, and the welding varieties can be more, and a variety of different materials can be welded.

f) No filler is required in the welding process, and the material utilization rate is high;

Application of Butt Welding

Automotive Manufacturing

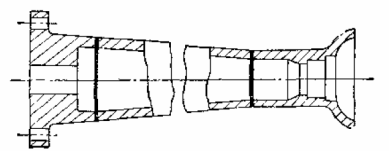

Figure 3. Automobile cardan shaft shell flash butt welding

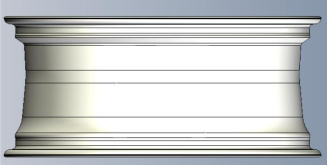

Figure 4. Automobile, motorcycle wheel flash butt welding

Aerospace industry

Figure 5. Aircraft rod butt welding

Petrochemical industry

Figure 6. Metal pipes butt welding

Construction engineering field

Figure 7. End plate flange butt welding

Shipbuilding industry

Figure 8. Anchor chain butt welding

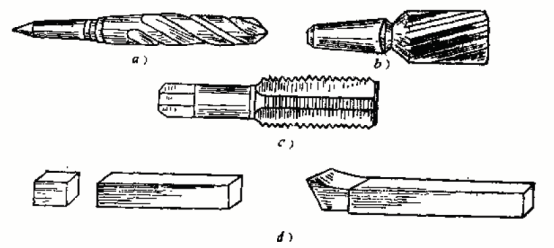

hardware tools

Flash butt welding machines are often used to weld hardware tools, such as knives, tweezers and pliers. Some power tool manufacturers will equip one such butt welding machine in their own factories.

Figure 9. Tool butt welding

Specification Parameters in Butt Welding Process

When proper parameters of butt welding specifications are selected, high quality joints with almost the same properties as base materials can be obtained.

a) The main specification parameters of resistance butt welding are:

stretching length, welding current density (or welding current), welding time, welding pressure and top forging pressure.

b) The main parameters of flash butt welding are:

Flash stage: adjusting stretch length, flash retention, flash speed, flash current density;

Top forging stage: top forging allowance, top forging speed, top forging pressure, clamping force;

Preheating stage: preheating temperature, preheating time.

The function of stretching length is to ensure the necessary allowance (welding part shortening) and adjust the temperature field when heating the significance and function can be selected according to the welding part section and material properties, practice shows that the stretching length should not be less than half of the diameter of the welding part, that is, l = 0.6~1.0d(d is the diameter of the timber or the side length of the square) is appropriate. At the same time, when welding dissimilar materials, in order to obtain a balanced temperature distribution (sometimes considering the rigidity of non-ferrous metal weldments), the two weldments should use different stretching lengths.

The welding current is often expressed by the current density, and the current density and welding time are the two main parameters that determine the welding heating, and can be appropriately adjusted to each other. In practice, it is recommended to maintain a certain relationship between the maximum current density and the minimum welding time, and to use a harder specification as the cross-section decreases. The current density of continuous flash butt welding, metal materials with good electrical and thermal conductivity, and welded parts with expanded section should be high. For preheating flash butt welding and large section welds, the current density should be low.

Both the welding pressure and the top forging pressure have an effect on the heat dissolution of the contact surface and the plastic deformation of the opposite and adjacent areas. The top forging speed and the top forging force pressure can be matched, and the top forging speed can be reduced appropriately when the top forging speed is large enough.

The Development Prospect of Butt Welding

With the in-depth study of the relationship between resistance welding quality and welding process parameters and on-line detection technology, more stable welding quality can be obtained. In addition, the welding materials have been further expanded, and the application range of resistance welding is more and more wide. With the continuous progress of resistance welding technology, resistance welding will occupy a more important position in the future industrial production. Especially in the welding field of large cross-section and dissimilar metals, flash butt welding has a good development prospect.

Summary

With the development of new energy industry, more and more welding applications of copper and aluminum connection, resistance welding technology just conforms to the needs of the market, combined with the new resistance welding process and adaptive control technology, resistance welding in the future development will usher in a greater boom.