The present and future of resistance welding – digital

With the continuous progress of science and technology and the increasing refinement of industrial production, resistance welding technology, as an important welding method, has been widely used in various fields. However, the traditional resistance welding technology has some problems, such as low control precision, high energy consumption and unstable welding quality. In order to solve these problems, digital technology is introduced into resistance welding technology, which greatly improves the automation level and welding quality of resistance welding.

Digital resistance welding

Digital resistance welding is a kind of welding technology that uses digital technology to accurately control and optimize the resistance welding process. It can realize real-time monitoring and automatic adjustment of welding process by digital processing of welding parameters, process data, equipment status and other information. Digital resistance welding has the following characteristics:

1. High control accuracy: digital resistance welding can accurately control welding current, voltage, time and other parameters to ensure the stability and consistency of welding quality.

2. High degree of automation: the digital resistance welding system can realize the automatic control of the welding process, reduce manual intervention and improve production efficiency.

3. Energy saving and environmental protection: By optimizing welding parameters and processes, digital resistance welding can reduce energy consumption and reduce emissions of pollutants such as waste gas and slag.

4. Strong traceability: the digital resistance welding system can record the data in the welding process, providing strong support for product quality traceability.

The importance of digitization in resistance welding

1. Improve welding quality: digital technology can accurately control welding parameters and processes to ensure the stability and consistency of welding quality and improve product quality.

2. Improve production efficiency: digital technology can realize the automatic control and optimization of the welding process, reduce manual intervention, and improve production efficiency.

3. Reduce production costs: By optimizing welding parameters and processes, digital resistance welding can reduce energy consumption and material consumption, and reduce production costs.

4. Enhance the competitiveness of enterprises: digital resistance welding technology can improve the technical level and management level of enterprises, and enhance the market competitiveness and sustainable development ability of enterprises.

Application of digitization in resistance welding

1. Welding parameter control

In the process of resistance welding, the control of welding parameters has an important effect on welding quality. Digital technology can monitor and adjust welding current, voltage, time and other parameters in real time to ensure the stability and consistency of the welding process.

2. Welding process optimization

The digital technology can automatically adjust welding process parameters according to welding materials, workpiece shape and thickness and other factors to realize the optimization of welding process. Through simulation and data analysis, the digital resistance welding system can predict the temperature field, stress field and other changes in the welding process, and provide scientific basis for process optimization. In addition, digital technology can also achieve remote monitoring and fault diagnosis of the welding process, improving the reliability and service life of the equipment.

3. Welding quality inspection

The digital technology can monitor and evaluate the welding quality in real time. By collecting the voltage, current, temperature and other parameters in the welding process, the digital resistance welding system can judge whether the welding quality meets the requirements. At the same time, digital technology can also conduct non-destructive testing of welded joints to find defects and hidden dangers in the welding process.

4. Intelligent management

The digital resistance welding system can realize the intelligent management of welding process. Through the integration of the Internet of Things, big data, cloud computing and other technologies, the digital resistance welding system can achieve real-time monitoring of equipment status, fault diagnosis and early warning maintenance. In addition, digital technology can also realize the visual display and data analysis of the welding process, providing strong support for production decisions.

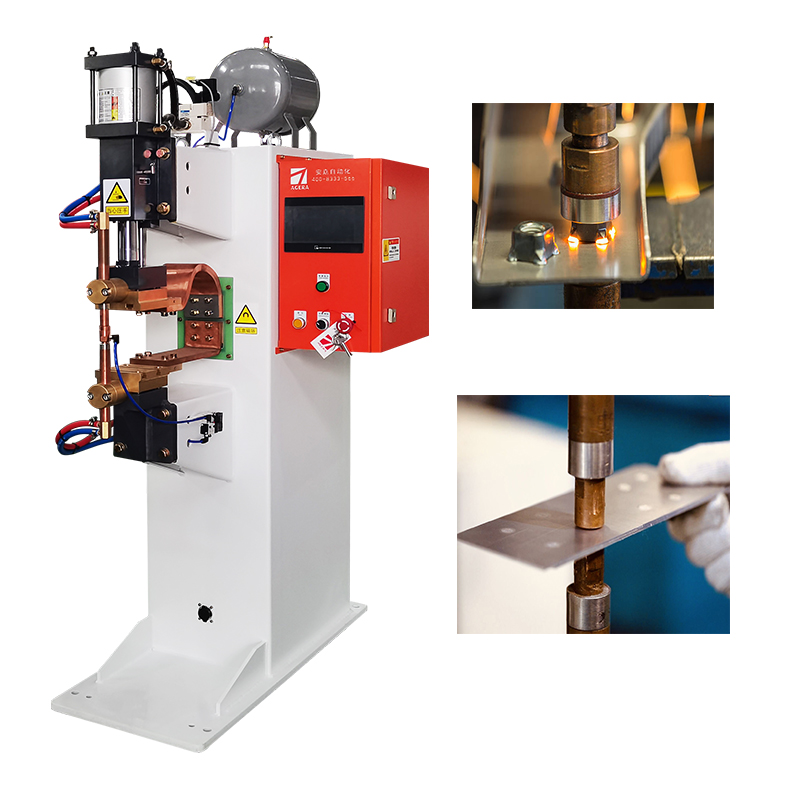

As the world’s leading metal connection solution provider, Agera is also constantly exploring the development path of digital resistance welding, and in 2022, it developed and manufactured the welding quality real-time monitoring system HRC650, which is a precision equipment. It can be used for high-speed real-time detection of current, secondary voltage, joint resistance, electrode displacement, electrode pressure data and curves that affect weld quality, and the limit range of each data can be set individually. If the data exceeds the specified value, you can output an alarm and set an envelope curve.

The application of digitalization in resistance welding technology has become an inevitable trend in the development of the industry. With the continuous development and improvement of digital technology, resistance welding technology will achieve a more efficient, accurate and intelligent welding process. In the future, Agera will continue to explore the road of digital resistance welding and provide strong support for the transformation and upgrading of industrial production.