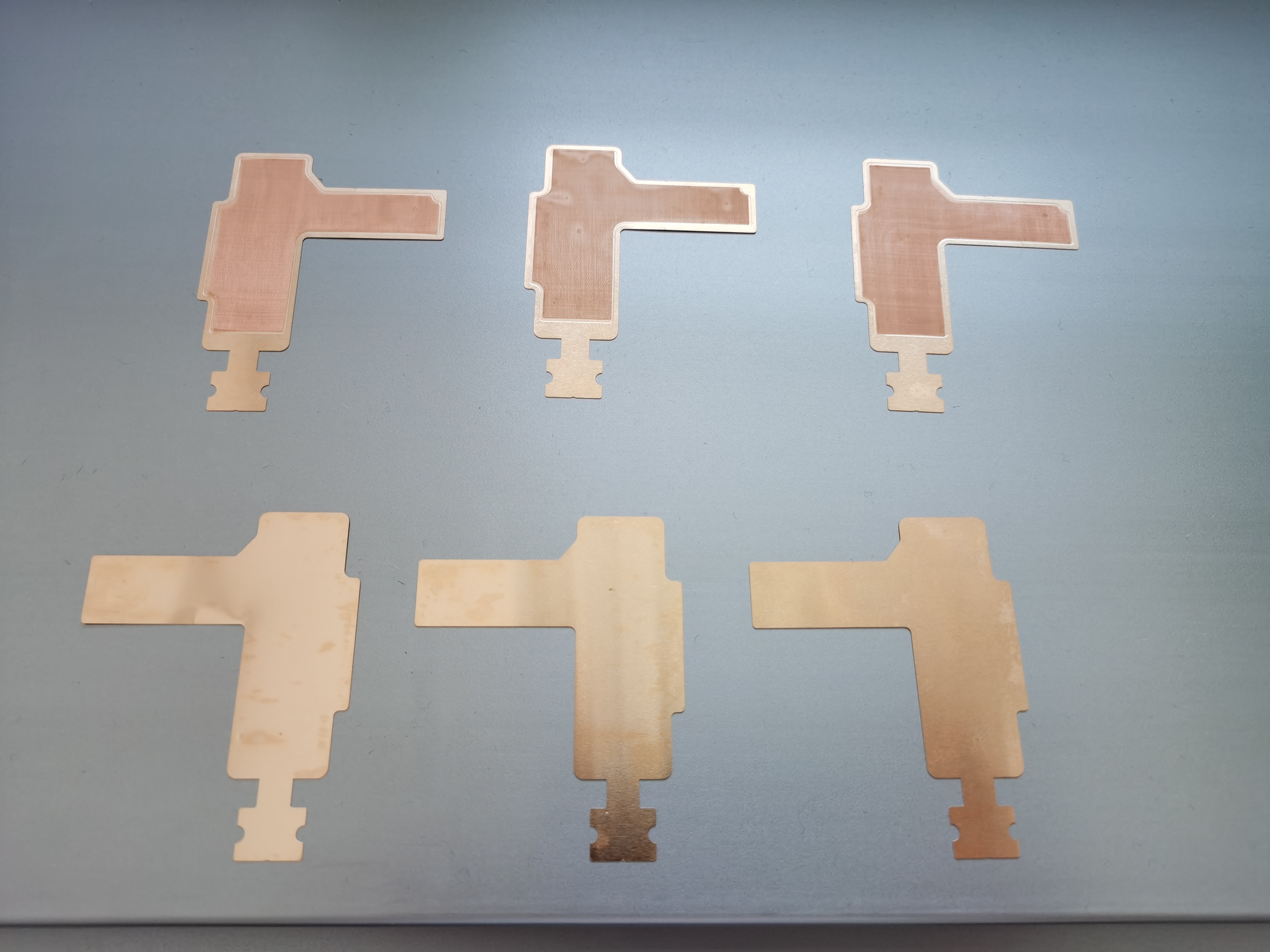

The 5G Mobile Phone Component Equalization Board Is Fixed

————- Spot welded (fixed) equalizing plate mesh

5G runs fast, and the heat dissipation design is particularly important. Upgrade from cooling copper tube to uniform temperature plate. How to be efficient and improve the yield is the importance of production. Before the uniform temperature plate, there is a rapid diffusion of filling water inside, such as fixing with a spot welding machine, which can reduce the equipment investment of high-priced brazing furnaces.

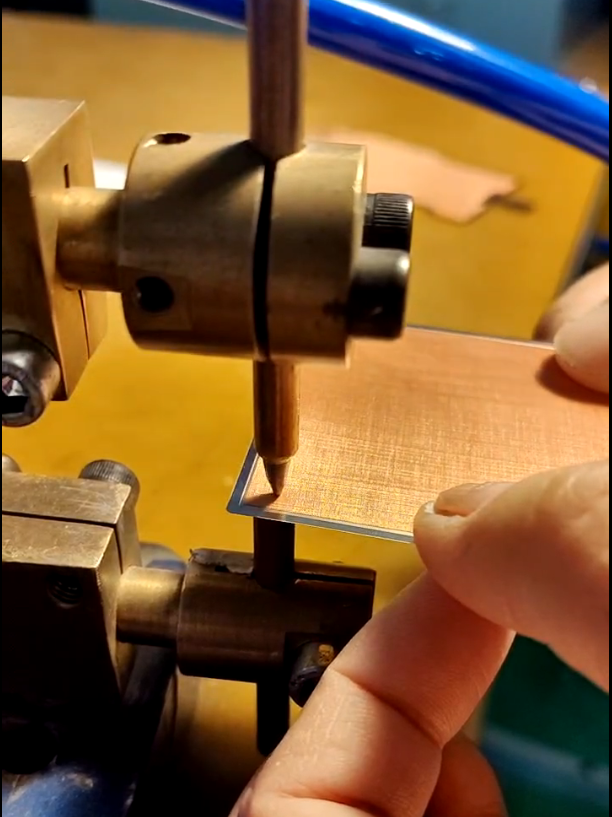

Precision spot welding can realize the uniform temperature plate copper alloy 0.14mm-0.22mm thick +0.38mm copper mesh welding (fusion fixed), and no trace. The electrical conductivity and heat dissipation of copper are very good, and the heat required for welding is difficult to produce, especially the ultra-thin temperature equalizing plate requires small pressure to improve the resistance heat and reduce heat dissipation in a short time. Therefore, the current control accuracy should be high and the pressure should be small. Precision spot welding machine, current rising speed, high control accuracy, current 0.01A accuracy setting, welding time 0.01ms setting.

Welding electrode, the upper electrode is made of copper-tipped tungsten material to enhance heat acceleration, the lower electrode is used first, and the flat head copper oxide electrode is used to make the copper plate edge without marks and reduce the probability of sticking.

Precision spot welding fixed copper sheet and mesh for the production process welding, not part functional requirements. However, it simplifies the production process, improves efficiency and reduces equipment investment.