Spot Welding Machine – Principle, Types, Advantages

Spot welding machine is a machine used for metal connection, which is relatively common in metal processing. With the progress of welding technology and the improvement of welding requirements, welding equipment is more and more diversified, spot welding machine is a kind of welding equipment with a long history, so far in the industry also plays a very important role. This article will explain the spot welding machine in detail, take you to understand its principle, types, advantages, etc.

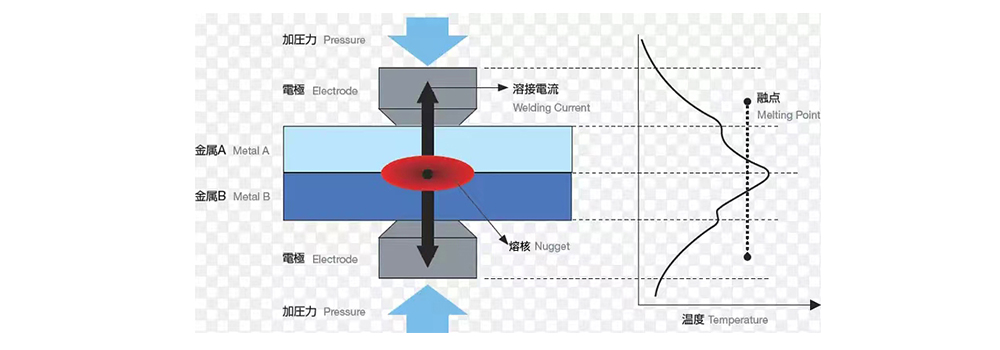

Principle of spot welding machine

Spot welding machine is a kind of resistance welding machine, this welding equipment is the use of current through the electrode and metal workpiece to generate resistance heat to provide heat source, through the way of heating and pressurizing the two metal contact is connected together. The electrode clamps two overlapping metal workpieces, this action is achieved by applying pressure through air pressure, the size of the pressure of the clamping workpiece mainly depends on the thickness of the material and the hardness of the material, the greater the thickness, the greater the required pressure value, the greater the hardness of the material, the greater the required pressure. When you are welding a new product with a spot welder, you can gradually adjust the pressure from small to large, during which the welded product is tested. Until you weld the product solder joint surface smooth, and the firmness to meet the requirements, this time the pressure value is the most appropriate.

In addition to welding pressure, welding current, welding time, contact resistance is also an important parameter of spot welding machine work, all affect the welding heat, the parameters complement each other, set the appropriate welding parameters in order to finally weld qualified products.

Type of spot welder

Due to the different working forms, we have divided the spot welding machine into 2 categories, Standard spot welding machine and customized spot welding machine.

Standard spot welder

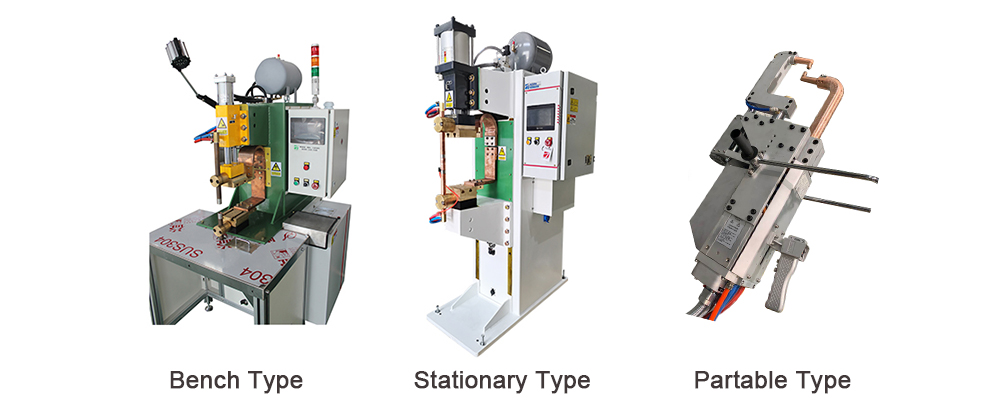

Bench type spot welder

Benchtop spot welding machine is generally relatively small power, more suitable for welding small metal products, such as electronic parts. This spot welding machine body is small, easy to move, generally placed on the workbench or table to use, the operator can sit to complete the welding work.

Stationary spot welder

The fuselage is large and heavy, the machine is not easy to move, and it is generally fixed in a certain position in the factory, so it is called a stationary spot welder. Compared with the desktop spot welding machine, the stationary spot welding machine is generally large power, more powerful welding capacity, and generally welding metal parts with larger thickness. For instance, it can be used for the casing of led poster, car nuts, spot welding of aluminum plates, etc. For safety reasons, foot switches are installed, and the operator can also pick up and release the work by hand.

Portable spot welding gun

Also called suspended spot welder, because it is generally suspended to operate. The body of the portable spot welding machine is small, can be moved 360 degrees, generally used for welding is not easy to move or beyond the scope of large welding machine welding products, such as body welding will often use this equipment. You can adjust the height to the right position, align the part that needs to be welded, hold the handle switch, and you can complete a welding job.

Automatic special spot welding machine

Multi-head spot welder

In addition to the above standard spot welding equipment, you can also customize a welding machine specifically for your product according to your product and welding requirements. For example, if you want to weld a sheet metal of relatively large size, the use of standard spot welding machine is not convenient to operate and the welding speed is slow. You can ask the manufacturer to design you a multi-head semi-automatic spot welder, which can weld multiple points at once, thereby improving welding efficiency. This spot welding machine is often used for the welding of sheet metal boxes, and the equipment cost is higher than the standard machine because it needs to be customized according to demand.

X Y axis spot welding machine

How to choose the right spot welder

Advantages of spot welder

Application of spot welding machine

Welding material

Spot welding machine is used for welding metal materials, often used for welding stainless steel, low carbon steel, galvanized steel, copper, aluminum and other materials, in addition to the welding of the same material, can also connect dissimilar metals. In addition to the sheet metal welding, the joint projection welding of nuts, bolts and sheets can also use spot welders.

Industry application

Spot welding machine is widely used in the industry, and metal processing can often see its figure. Spot welding machine is mainly used in automobile manufacturing, electronic and electrical, household appliances, sheet metal cabinets, machinery manufacturing and other industries. Whenever you need a metal connection, you will most likely use a spot welder.

Summery

The above is a brief introduction to the spot welding machine, if you are looking for a suitable spot welding machine, this article should be able to get the answer. Choosing a suitable spot welding machine is very important, a good spot welding machine can create a more competitive product for you, a bad machine will reduce your work efficiency. You can also contact Agera spot welding machine manufacturers, we will recommend the right model for you.