Resistance Welding Harness Pressure Square

With the development of The Times, the rise of new energy vehicles, new energy vehicles will use a lot of wiring harness to give the entire car electrical connection, wiring harness connection and fastening will use resistance welding to weld, let’s take a look at it!

What is resistance welding?

The workpiece to be connected is placed between the two electrodes under pressure, and the welding place is heated with current, and the heat generated by the workpiece resistance is heated and the local melting or the new state is reached. After the power is cut off, the firm joint is formed under the continuous action of pressure. This process is called resistance welding.

The advantages of resistance welding

Simple operation, no need to add gas protection, no need to add metal solder, low welding cost, easy to achieve automatic welding, welding parameters are all digital visual, can store multiple sets of formula, welding different products, only need to pick up the corresponding specification number or formula can be, the operator’s skill requirements are not high!

Common wiring harness pressure of new energy vehicles:

Welding more common wire harness pressure square are: copper braided tape, cable harness pressure square welding: specifications 16,25,35,50,75,95,120mm square cable, according to the performance requirements of various wire harnesses, determine the compression ratio for pressure square welding.

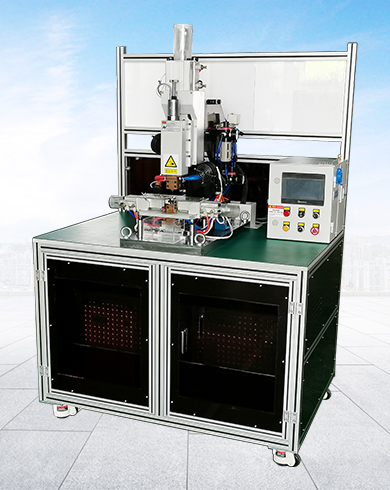

What welding machine is used in the pressure square?

When the voltage square is preferred, the medium frequency DC inverter spot welding machine has the characteristics of reliable welding current, high power factor and small voltage drop to the grid. According to the welding requirements, some special welding fixtures can be made, so that the welded joints are smooth and beautiful, and can also improve production efficiency.

Can wire harness achieve automatic welding?

The answer is yes, usually our cable, copper braided tape are coil material, wire harness automatic welding and cutting machine, can do automatic feeding, automatic welding, cutting. Cutting can be based on customer requirements, set length, to meet customer welding requirements of various specifications. The control part of the equipment is equipped with a large screen touch screen, the welding parameters are digitally displayed, multiple sets of formula can be selected, different formulas can be stored according to different products, and the corresponding formula number can be called next time, simple and convenient, high efficiency!

Small batch, multi-specification, how to choose welding equipment?

At the beginning of many customers, it is a small batch, a variety of specifications of products, at this time, this time we can choose a single pressure square welding machine, features: can quickly replace the welding electrode to meet the needs of various products, simple structure, good welding effect, procurement cost compared to the price of automatic welding equipment has a great advantage!

If you are looking for a copper wire pressure square method, you can try to use a resistance welding machine, you may have never touched before, but it will definitely give you a surprise.