- Home

- News

- Resistance Spot Welding in the Automotive Industry: A Key to Efficient Vehicle Manufacturing

Resistance Spot Welding in the Automotive Industry: A Key to Efficient Vehicle Manufacturing

Resistance spot welding (RSW) stands as one of the most vital and widely-used welding processes in the automotive manufacturing sector. As vehicles require thousands of secure joints in their body structures, this efficient method has become indispensable for auto manufacturers worldwide. Let’s explore how this technology continues to drive innovation and quality in automobile production.

The Fundamentals of Resistance Spot Welding

Resistance spot welding is a process that joins metal surfaces by applying pressure and passing a strong electric current through the workpieces. The electrical resistance of the metals generates intense heat, effectively fusing them together at specific points. This method offers numerous advantages including high speed, consistency, and the ability to automate the process completely—all crucial factors in high-volume automotive production environments.

Extensive Applications in Automotive Manufacturing

Automobile Body Assembly

The automobile body-in-white (BIW) structure relies heavily on resistance spot welding. Approximately 60% of welding joints in automobile manufacturing are completed using resistance spot welding machines. A typical passenger car body contains between 3,000 to 4,000 individual spot welds, with some sources even estimating this number to be as high as 3,500-5,000 for certain vehicle models. These welds join various stamped sheet metal components to form the vehicle’s fundamental structure.

RSW is extensively used in assembling critical body components including:

l Floor pans and structural reinforcements

l Side frames and pillar structures

l Roof frames and supports

l Door assemblies and closure systems

l Body-on-frame constructions

Automotive Components Production

Beyond the main body structure, resistance spot welding plays a crucial role in manufacturing various automotive components:

l Frame and chassis components

l Bracket assemblies and reinforcements

l Seat frame structures

l Exhaust system components

l Various interior structural elements

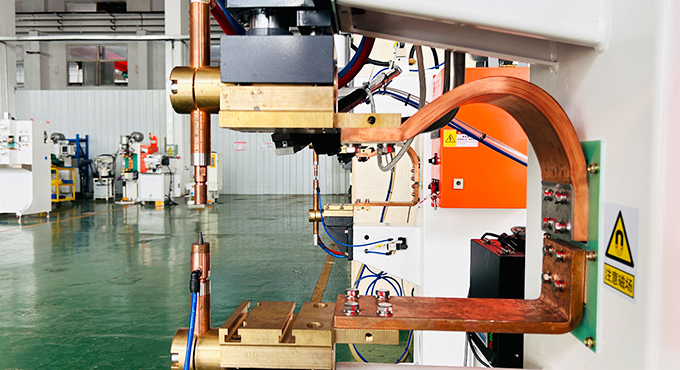

Types of Resistance Spot Welding Equipment in Automotive Plants

Automotive manufacturing facilities typically utilize three main types of resistance spot welding equipment:

1. Stationary Spot Welding Machines

These fixed machines provide consistent performance for specific, repetitive welding operations, particularly in component sub-assembly areas.

2. Robotic Spot Welding Systems

Modern automotive plants increasingly employ robotic welding systems for their flexibility, precision, and efficiency. These systems incorporate:

Inverter welding technology that reduces transformer weight and size

Integrated transformer-welding gun assemblies that improve robot maneuverability

Automatic tool changers that allow quick adaptation to different welding requirements

Advanced control systems that monitor and adjust welding parameters in real-time.

3. Portable Spot Welding Guns

Suspended portable welders offer flexibility for hard-to-reach areas or for operations where moving the component is impractical. Recent trends show a shift toward integrated suspended spot welders (where the controller and transformer are combined) rather than separated systems, with approximately 90% of recent installations being the integrated type.

Technological Advancements in Resistance Spot Welding

Intelligent Resistance Spot Welding Systems

Modern systems like the Newton Ring® Intelligent Resistance Spot Welding System (NTR-FE-01) represent the cutting edge of RSW technology. These advanced systems offer significant benefits including:

Enhanced joint mechanical performance and nugget size stability

Dramatic reduction of surface sticking and damage at weld points

Extension of electrode service life by 3 times or more

Substantial expansion of weldable material ranges

Advanced Control and Monitoring Capabilities

Contemporary resistance welding controllers incorporate sophisticated features that ensure consistent quality:

Constant current control that compensates for power supply fluctuations

Multiple preset welding programs for different applications

Power factor adaptive control for improved energy efficiency

Electrode wear compensation and replacement alert systems

Fault diagnosis and alert functions

Network integration capabilities for centralized management of multiple welders

Addressing Material Challenges in Modern Automotive Design

As the automotive industry increasingly adopts advanced high-strength steels (AHSS) to reduce vehicle weight while maintaining safety standards, resistance spot welding technology has evolved accordingly. These materials, including dual-phase steels (such as DP780), complex-phase steels, transformation-induced plasticity (TRIP) steels, and quenching and partitioning (Q&P) steels, present unique welding challenges that require precise control of welding parameters.

Additionally, the growing application of galvanized steels for corrosion resistance necessitates specialized welding approaches to ensure consistent joint quality while preventing defects such as cracks, shrinkage voids, and spatter that can adversely affect the mechanical performance of welded joints.

Quality Assurance and Digital Implementation

The automotive industry maintains stringent quality standards for resistance spot welding, with specific visual and measurable acceptance criteria for resistance spot welds in steels. Automotive manufacturers are increasingly implementing digital solutions for their resistance spot welding operations to enhance body strength quality assurance capabilities and improve quality efficiency.

Comparison with Alternative Joining Methods

While laser welding has emerged as a potential alternative for some automotive applications, resistance spot welding maintains several advantages that ensure its continued dominance for many applications:

Lower initial equipment investment

Less demanding joint fit-up requirements

Proven reliability with extensive industry experience

Large existing knowledge base of skilled technicians and engineers

Established quality monitoring systems

The Future of Resistance Spot Welding in Automotive Manufacturing

As vehicle structures continue to evolve, resistance spot welding technology is adapting to meet new challenges:

Integration with Industry 4.0 systems for real-time monitoring and data analytics

Development of more sophisticated quality monitoring systems including dynamic resistance, thermal expansion, ultrasonic, and infrared monitoring

Improved energy efficiency through advanced transformer designs and control systems

Enhanced flexibility to accommodate mixed-material vehicle structures

Reduced environmental impact through optimized energy consumption and longer electrode life

Conclusion

Resistance spot welding remains an indispensable technology in automotive manufacturing, combining efficiency, reliability, and cost-effectiveness. As vehicles continue to evolve with new materials and designs, RSW technology adapts and advances to meet these changing demands. From traditional steel structures to advanced high-strength materials, resistance spot welding continues to provide the automotive industry with the joining solutions needed to produce safe, durable, and high-quality vehicles.

For automotive manufacturers seeking to optimize their production processes, resistance spot welding offers a proven, adaptable, and continually improving solution that stands ready to meet the challenges of modern vehicle manufacturing.