A Guide to Welding Stainless Steel

Welding stainless steel requires specialized techniques and careful preparation due to its unique properties. Stainless steel is widely used in industries such as food processing, pharmaceuticals, aerospace, and construction due to its high corrosion resistance, strength, and aesthetic appeal. However, these same qualities also make it more challenging to weld compared to mild steel.

In this guide, we’ll cover the fundamental principles of welding stainless steel, the challenges it presents, and the best practices for achieving high-quality welds. Whether you’re a beginner or an experienced welder, understanding these concepts will help you get consistent results when working with stainless steel.

Properties of Stainless Steel

Stainless steel contains at least 10.5% chromium, which forms a passive oxide layer on the surface, giving it corrosion resistance. Various types of stainless steel, such as austenitic, ferritic, martensitic, and duplex, offer different combinations of strength, weldability, and resistance to corrosion.

The properties of stainless steel that impact welding include:

High Thermal Expansion: Stainless steel expands more than carbon steel when heated, increasing the risk of warping and distortion during welding.

Low Thermal Conductivity: Heat is not easily dissipated, leading to a concentration of heat at the weld joint, which can cause burn-through.

Sensitivity to Heat: Excessive heat input can cause discoloration or reduce corrosion resistance.

Formation of Carbides: Chromium carbide formation can occur at high temperatures, reducing corrosion resistance (a phenomenon known as sensitization).

Types of Stainless Steel for Welding

1. Austenitic Stainless Steel (300 Series)

Characteristics: Non-magnetic, highly corrosion-resistant, and easy to work with.

Common Grades: 304 and 316.

Weldability: Good, but prone to distortion due to high thermal expansion.

2. Ferritic Stainless Steel (400 Series)

Characteristics: Magnetic, lower corrosion resistance than austenitic types but higher thermal conductivity.

Common Grades: 430.

Weldability: Moderate; requires pre- and post-weld heat treatment to avoid cracking.

3. Martensitic Stainless Steel

Characteristics: High strength, wear resistance, and limited corrosion resistance.

Common Grades: 410 and 420.

Weldability: Difficult; requires careful control of heat to avoid cracking.

4. Duplex Stainless Steel

Characteristics: A mix of austenitic and ferritic properties, offering high strength and corrosion resistance.

Common Grades: 2205.

Weldability: Requires low heat input to prevent embrittlement.

Welding Methods for Stainless Steel

Best for: Thin stainless steel sheets and applications requiring high precision.

Advantages: Clean, precise welds with minimal spatter.

Considerations: Requires a skilled operator and slower welding speed.

Best for: Larger projects where speed is important.

Advantages: Faster than TIG welding and easier to learn.

Considerations: Can produce spatter and requires shielding gas (often argon or a mix with CO₂).

Best for: Outdoor projects and thicker stainless steel parts.

Advantages: Doesn’t require shielding gas, making it suitable for outdoor work.

Considerations: Can be difficult to control on thin stainless steel.

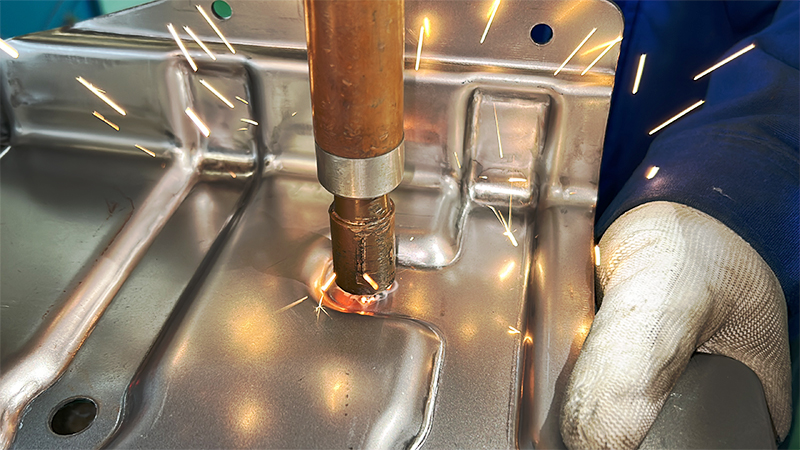

Best for: Thin sheets in automotive and industrial applications.

Advantages: Fast and efficient for overlapping joints.

Considerations: Limited to specific joint types.

Best Practices for Welding Stainless Steel

Preparation

Clean the surfaces thoroughly to remove dirt, grease, and oxidation. Contaminants can cause weld defects and reduce corrosion resistance.

Use dedicated tools (brushes, grinders) for stainless steel to prevent contamination from other metals.

Shielding Gas Selection

For TIG welding, use 100% argon or an argon-helium mix.

For MIG welding, a mix of argon and CO₂ or oxygen improves weld penetration and stability.

Control Heat Input

Use the lowest possible heat input to avoid warping, discoloration, and carbide formation.

If possible, use pulse welding to control the heat flow more precisely.

Minimize Distortion

Clamp the workpieces tightly to minimize movement during welding.

Use backstepping (welding small sections in alternating directions) to distribute heat more evenly.

Post-Weld Cleaning and Finishing

Remove any discoloration with stainless steel wire brushes or chemical cleaners to restore corrosion resistance.

Use passivation techniques to remove surface contamination and enhance the oxide layer.

Avoiding Cracks and Sensitization

For thicker sections, preheating the metal can help reduce the risk of cracking.

Use low-carbon grades (such as 304L or 316L) to avoid chromium carbide formation.

Common Defects in Stainless Steel Welding

Warping and Distortion: Caused by excessive heat input and thermal expansion.

Burn-Through: Occurs when the heat melts through the material, often seen with thin metals.

Cracking: Typically due to poor heat management or contamination.

Porosity: Caused by trapped gases in the weld pool, often due to inadequate shielding gas.

Discoloration: Overheating can cause oxidation, resulting in a rainbow-colored surface.

Applications of Stainless Steel Welding

Food Processing Equipment: Stainless steel is commonly used for tanks, pipes, and surfaces in food production due to its corrosion resistance and ease of cleaning.

Pharmaceutical and Medical Devices: Surgical instruments, implants, and sterile containers require precise, clean welds.

Aerospace Industry: Stainless steel is used in aircraft components for its strength and resistance to high temperatures.

Architecture and Construction: Handrails, facades, and other structural elements use stainless steel for durability and aesthetics.

Automotive Industry: Exhaust systems, fuel tanks, and decorative trim are often made from stainless steel.

Conclusion

Welding stainless steel is both a science and an art, requiring an understanding of the material’s unique properties and challenges. With the right techniques, preparation, and equipment, you can achieve high-quality, durable welds that maintain the material’s strength and corrosion resistance.

Whether you’re fabricating components for the food industry, constructing an architectural feature, or building high-performance automotive parts, stainless steel welding offers a combination of beauty, durability, and functionality. Following best practices and selecting the appropriate welding method will ensure successful outcomes for your stainless steel welding projects.