Causes of Incomplete Fusion in Spot Welding?

Incomplete fusion, commonly known as “cold weld” or “lack of fusion,” is a critical issue that can occur during spot welding processes using spot welding machines. It refers to a condition where the molten metal fails to fully fuse with the base material, resulting in a weak and unreliable weld joint. This article aims to explore the various factors that can lead to incomplete fusion in spot welding.

Welding Current

Welding current is one of the most important parameters in the welding process, and it has a multiplier effect on the heat generated during welding. Insufficient welding current is one of the main reasons for non-fusion. When the welding current is too low, it may not generate enough heat to fully melt the substrate. As a result, the molten metal cannot penetrate and fuse properly, resulting in incomplete fusion at the welding interface.

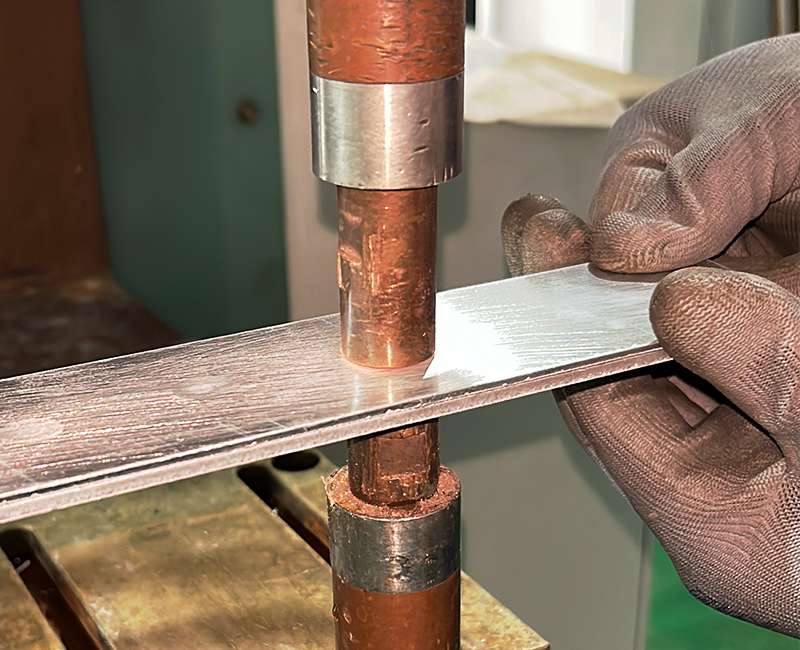

Insufficient Electrode Pressure

Insufficient electrical force can also lead to incomplete fusion. Electrical pressure is applied to the workpiece to ensure correct contact and penetration during welding. If the electrical force is too low, the contact area between the workpiece and the workpiece is small, when welding, the atomic movement of the solder joint will be insufficient, so that the two solder joints are likely not fully fused.

Electrode Alignment Is Incorrect

Incorrect alignment of electrodes can lead to uneven heat distribution, resulting in incomplete fusion. When the electrodes are not aligned, the heat generated during the welding process may not be evenly distributed throughout the welding area. This uneven heat distribution can lead to incomplete fusion in local areas. Therefore, before the welding work begins, be sure to check whether the upper and lower electrodes are accurate, if not aligned, it is necessary to align them through the tool.

Workpiece Surface Contamination Or Oxidation

Contamination or oxidation of the workpiece surface can interfere with normal fusion during spot welding. Contaminants, such as oil, dirt, or coatings, act as a barrier between the molten metal and the substrate, inhibiting melting. Similarly, surface oxidation can form a layer of oxide that prevents proper bonding and fusion. For example, when you want to weld the fin machined by the fin tube machine on the tube, if the surface of the tube is rusty, the welding must be non-fusion, so that the welded joint will be unstable and affect the quality of the product.

Short Welding Time

Insufficient welding time prevents the molten metal from flowing sufficiently and combining with the base material. If the welding time is too short, the metal contact is not fully fused before the end of the discharge, and this insufficient combination will lead to weak and unreliable welding.

Understanding the factors that lead to incomplete spot welding fusion is critical to ensuring high quality welds. By solving the problems of insufficient welding current, insufficient electrical force, improper electrode alignment, surface contamination or oxidation, and insufficient welding time, you can minimize the occurrence of incomplete fusion when welding work, so that the overall welding quality can be greatly improved.